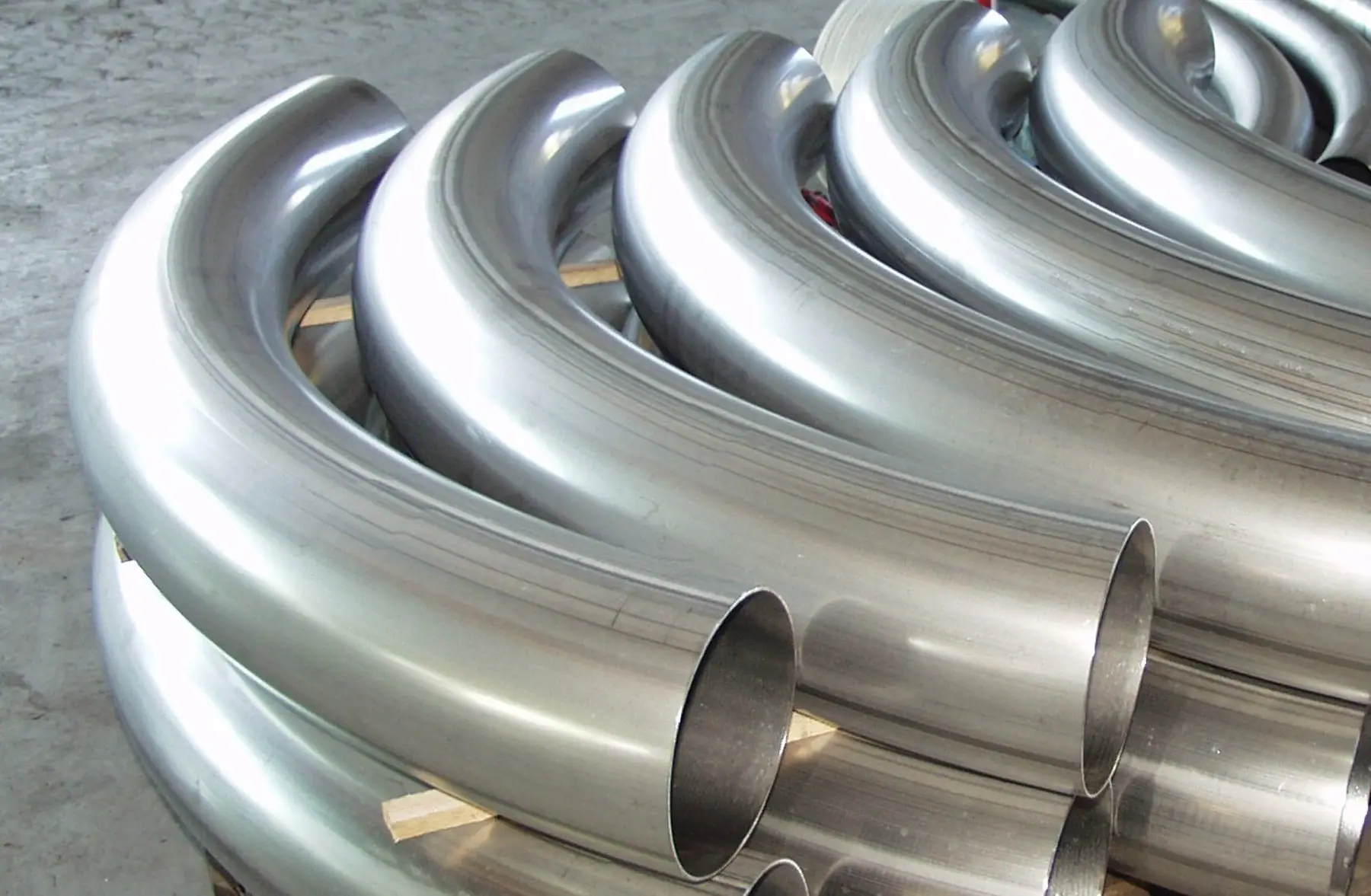

PIPE BEND

Pipe bending is a metal forming technique that permanently shapes pipes or tubing into various angles and directions, increasing fabrication capabilities for plumbing and industrial applications.

This versatile process creates smooth, continuous flow paths in piping systems while maintaining structural integrity and minimizing pressure drops compared to traditional elbow fittings.

Pipe bending encompasses various metal forming processes to create precise, permanent curves in piping systems. The simplest bend creates a 90-degree elbow, but modern techniques allow for complex 2D and 3D geometries. Pipe bending differs from tube bending primarily in wall thickness and application, with pipes typically having thicker walls for higher pressure applications. The process can be categorized into form-bound and freeform-bending procedures, as well as heat-supported and cold forming methods. Rotary draw bending, one of the most common techniques, allows pipes to be curved to tight radii with minimal distortion, making it ideal for process piping systems where flow efficiency is critical.

Pipe bends are classified by their centerline radius relative to the pipe diameter (D):

| Bend Type | Radius | Typical Applications |

|---|---|---|

| Short Radius (1D) | 1 × pipe diameter | Compact installations where space is limited |

| 2D Bend | 2 × pipe diameter | General process piping |

| 3D Bend | 3 × pipe diameter | Standard for most industrial applications |

| 5D Bend | 5 × pipe diameter | High-pressure systems, slurry pipelines |

| 8D-10D Bend | 8-10 × pipe diameter | Critical flow applications, large diameter pipes |

Example: For a 10-inch diameter pipe, a 5D bend would have a 50-inch centerline radius (10" × 5 = 50").

Various bending techniques are employed depending on material, wall thickness, and application requirements:

| Parameter | Specification |

|---|---|

| Materials | Carbon steel, stainless steel, alloy steels, duplex, nickel alloys |

| Size Range | 1/2" to 48" diameter (12mm to 1200mm) |

| Wall Thickness | Schedule 5S to XXS |

| Bend Angles | 15° to 180° (custom angles available) |

| Tolerances | ±1° on angle, ±1% on radius, ovality < 8% |

| Standards | ASME B16.9, B16.28, MSS SP-75, API 5L, ISO 15590 |

| Surface Finish | Mill, polished, coated (FBE, 3LPE, galvanized) |

Pipe bends serve critical functions across numerous industries: